Cov khoom

Semi-automatic Gummy Khoom Qab Zib Dais Khoom Qab Zib suav Qhov hnyav Lub raj mis Filling Packing Tshuab

1.Kev siv lub tshuab

Nws yog tsim rau hnyav thiab sau qoob loo, lo, hlais, globose, cov khoom tsis zoo xws li khoom qab zib, chocolate, jelly, pasta, melon noob, txiv laum huab xeeb, pistachios, almonds, cashews, ceev, kas fes taum, chips thiab lwm yam khoom noj lom zem, raisins, plum, cereals, tsiaj noj, puffed zaub mov, txiv hmab txiv ntoo, roasted noob, me me hardware, thiab lwm yam mus rau hauv lub kaus poom los yog lub thawv.

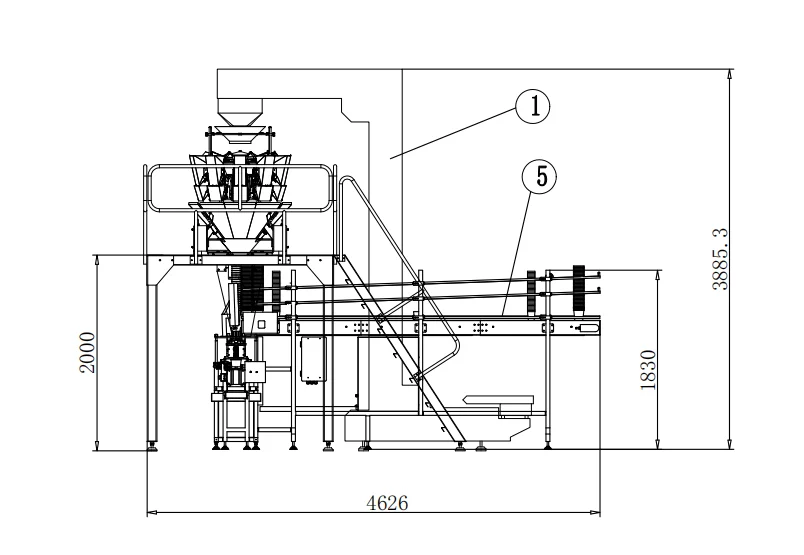

2.Kev piav qhia ntawm ZH-BC10 tuaj yeem sau thiab ntim qhov system

| Technical nta | |||

| 1. Cov khoom siv thauj khoom, hnyav, txhaws, capping, thiab hnub luam ntawv tiav tiav. | |||

| 2. Siab hnyav precision thiab efficiency. | |||

| 3. Ntim nrog tuaj yeem yog txoj hauv kev tshiab ntawm cov khoom ntim. |

| Technical Specification | |||

| Qauv | ZH-BC10 | ||

| Packing ceev | 15-50 Cans / Min | ||

| System Output | ≥8.4 Tuj / Hnub | ||

| Ntim Qhov tseeb | ± 0.1-1.5g | ||

| System Unite | |||

| aZ Shape thoob of elevator | Nqa cov khoom rau ntau lub taub hau hnyav uas tswj qhov pib thiab nres ntawm lub hoister. | ||

| b.multihead hnyav | Siv rau qhov hnyav. | ||

| c. Ua haujlwm platform | Txhawb lub multihead weighter. | ||

| d. Ncaj conveying kab | Thawv lub thawv. | ||

| e.Lub thawv pub zaub mov | Rau lub thawv pub. | ||

| f.Lub sij hawm hopper nrog dispenser | Rau kev sau cov khoom thiab dispenser rau tso tawm cov khoom. | ||

| g.Tswj lub thawv | Rau kev tswj tag nrho cov kab. | ||

3. Cov ntsiab lus ntxiv ntawm kev ntim khoom